2/2/06

I ordered kit 7 this morning.

2/2/06

I ordered kit 7 this morning.

2/2/06

I ordered kit 7 this morning.

2/2/06

I ordered kit 7 this morning.

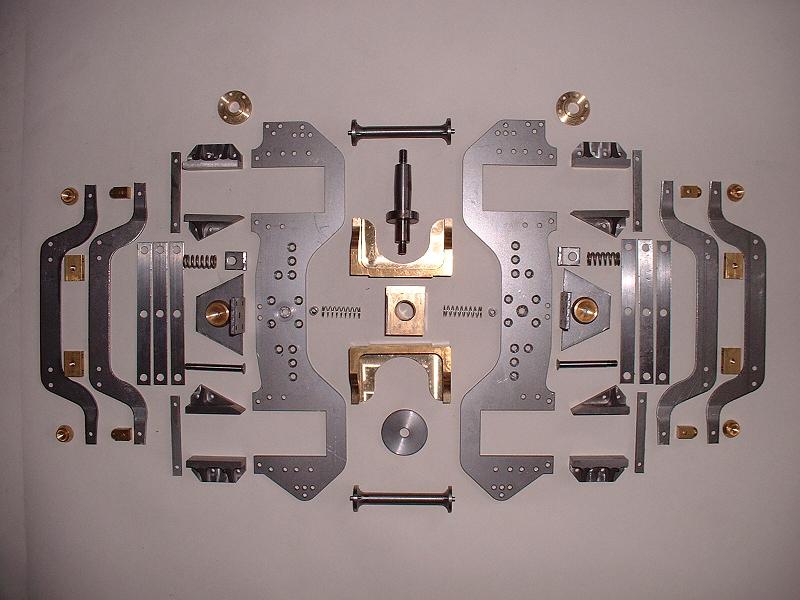

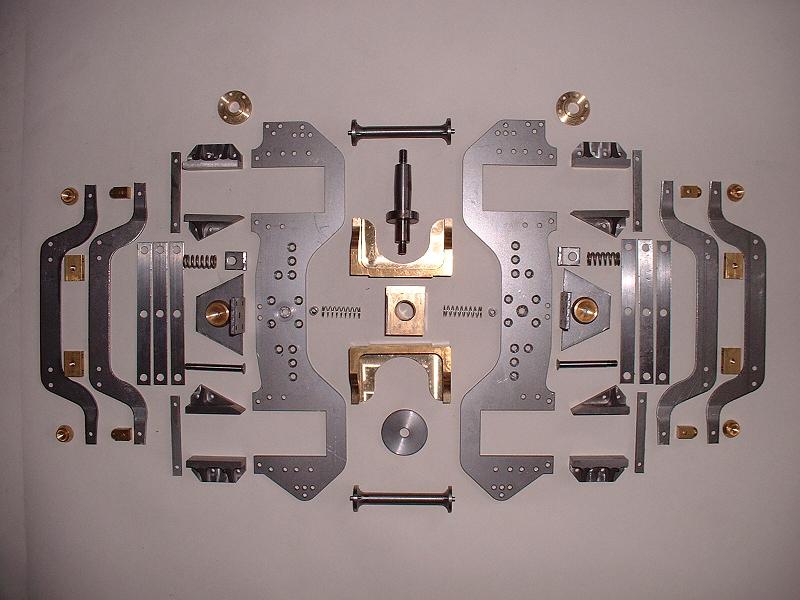

3/2/06 Kit 7 arrived at 8.15 this morning. I checked and photographed the parts - all present and correct as usual. The kit consists of:

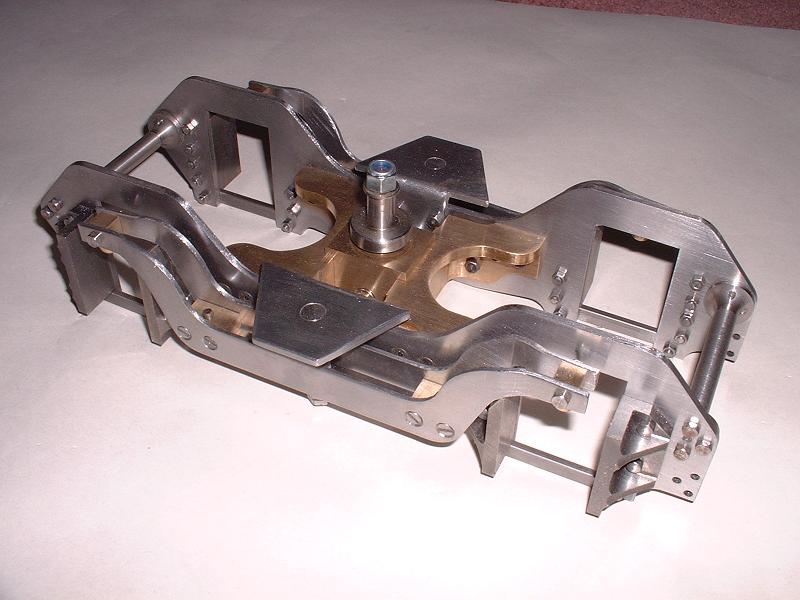

4/2/06 I've filed, polished and assembled the frames, stretchers, pressure brackets and the mounting block with its springs and pivot pin. This all fitted together very nicely, with two minor exceptions - the springs can fall out of their sockets if the mounting block is pushed right over to one side, and there is about 3mm of vertical free play on the pivot pin, which is sufficient for the pressure pads to fall out if the locomotive is lifted with the bogie dangling below. I can fix both these problems easily enough, by fitting locating pins for the springs into the sides of the mounting block and by reducing the shoulder on the pivot pin, but I'll check with Modelworks on Monday before doing so.

5/2/06 I've been contacted by Ian, who started building the Britannia in November and is now on kit 3 of the tender - that's a total of five builders with whom I'm in contact. If there are more of you out there reading this - and I now have about 45 visitors a day to the website - please do make contact! I assembled the equaliser bars and their springs and fitted them under the pressure brackets. The springing is not entirely authentic - it consists of three leaf springs with a coil spring above, rather than a complete set of leaf springs. However, this will hardly be visible once the cylinders are fitted over the bogie.

6/2/06 I bolted on the hornblocks, and I made and fitted a new set of horn stays from 1/4"x1/8" steel bar since the ones supplied were all slightly twisted. I also fixed the brass lifting eyes into the main frames - I had to Loctite the rivets because they were not long enough to rivet properly.

7/2/06

Debbie at Modelworks has agreed with the fixes proposed above, so I have drilled and tapped the spring recesses in the mounting block and inserted 6mm M3 bolts with locknuts so that the bolt heads are about 2mm above the surrounding surface of the block. This prevents the springs falling out, and also prevents the block travelling beyond the end of the machined faces, which I guess is what the designer intended. I have also ground about 2mm off the lower shoulder of the pivot pin (by spinning it in the drill and using a grinding wheel in the Dremel - I don't have a lathe), which reduces the vertical free play of the bogie to about 1-2mm and prevents the pressure pads from falling out. This completes kit 7. I'll do some more work on the tender and the pony spring struts before ordering kit 8, the driving wheels, next week.

7/2/06

Debbie at Modelworks has agreed with the fixes proposed above, so I have drilled and tapped the spring recesses in the mounting block and inserted 6mm M3 bolts with locknuts so that the bolt heads are about 2mm above the surrounding surface of the block. This prevents the springs falling out, and also prevents the block travelling beyond the end of the machined faces, which I guess is what the designer intended. I have also ground about 2mm off the lower shoulder of the pivot pin (by spinning it in the drill and using a grinding wheel in the Dremel - I don't have a lathe), which reduces the vertical free play of the bogie to about 1-2mm and prevents the pressure pads from falling out. This completes kit 7. I'll do some more work on the tender and the pony spring struts before ordering kit 8, the driving wheels, next week.

12/2/06 I've done more work on the tender and pony spring struts and written this up under kits 4 and 6. I've been contacted by Edward, who has built up to kit 12 and will soon be ready to test on compressed air, and is thus the furthest advanced of all the builders I know of. I'll order kit 8 tomorrow.

| Next Kit | Previous Kit | Index |