Kit 17 - Boiler and Superheater

9/11/06

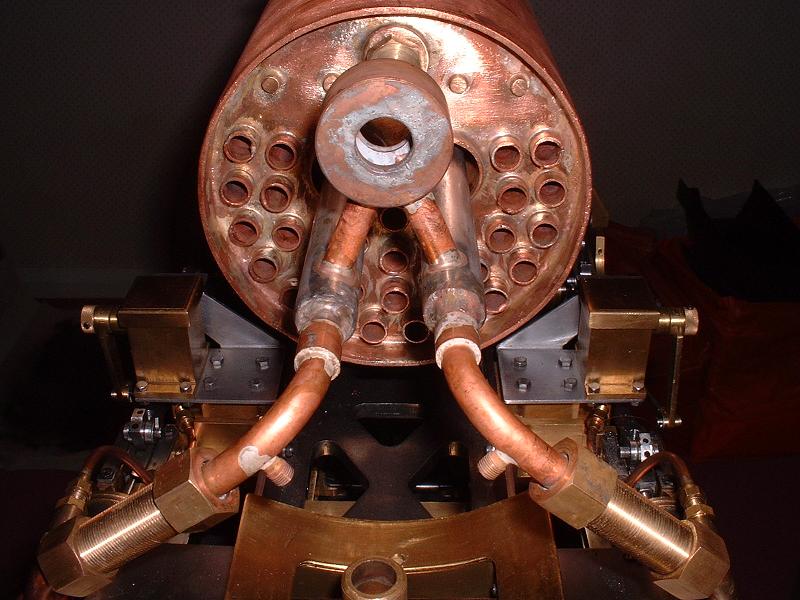

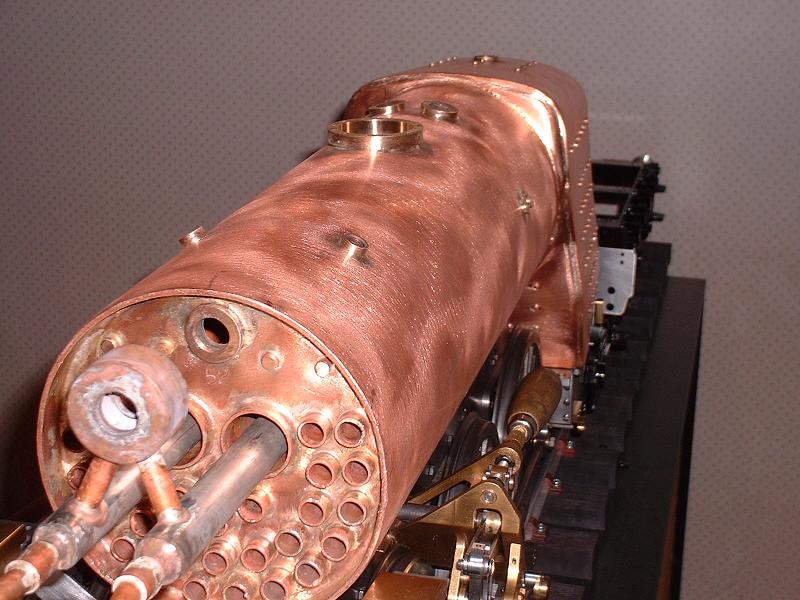

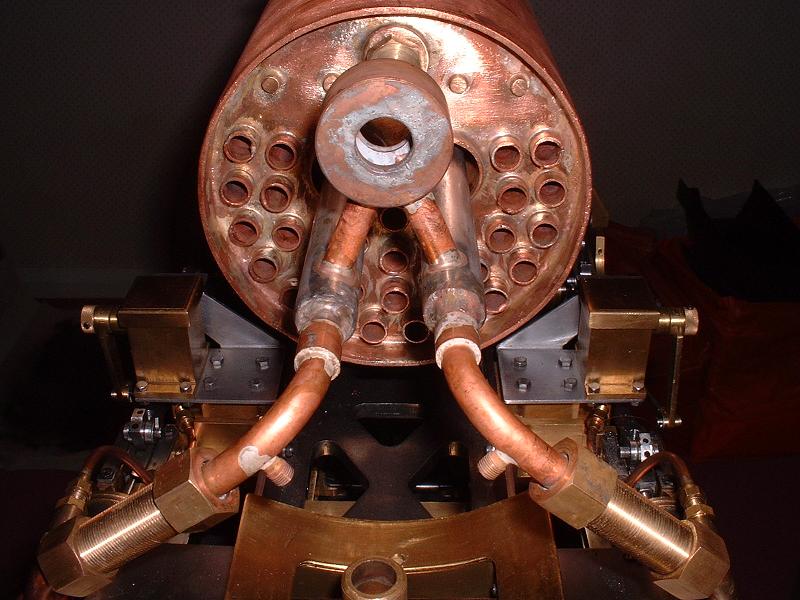

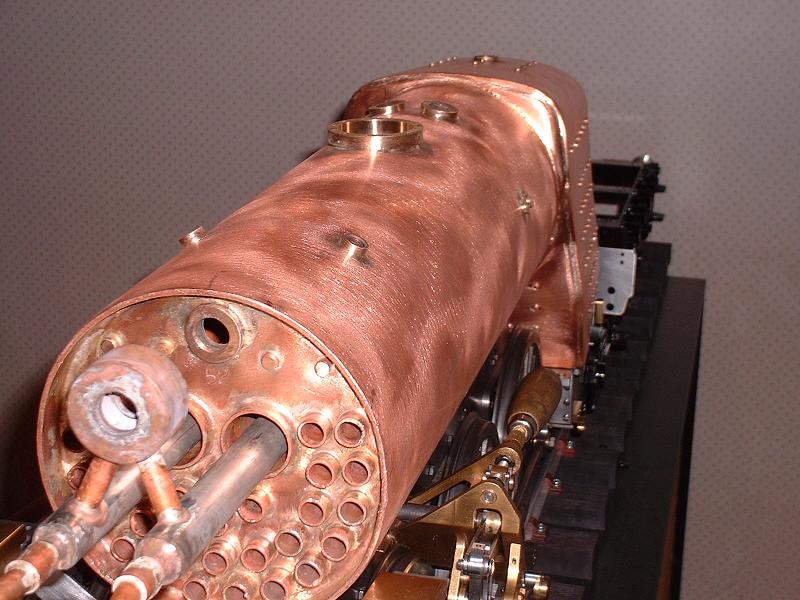

I visited the factory today to collect my boiler. It's a very impressive piece of craftsmanship - 26 kilos of copper, beautifully silver soldered. It comes with a test certificate and CE declaration of conformity, having been pressure tested to 200 psi with a working pressure of 90 psi. The kit also contains the superheater assembly, the dome cover, and the fusible plug for the firebox. The superheaters consist of concentric inner and outer tubes, with the outer stainless steel tubes having caps welded onto their rear ends. There's nothing to assemble at this stage, apart from screwing the fusible plug into the top of the inner firebox.

9/11/06

I visited the factory today to collect my boiler. It's a very impressive piece of craftsmanship - 26 kilos of copper, beautifully silver soldered. It comes with a test certificate and CE declaration of conformity, having been pressure tested to 200 psi with a working pressure of 90 psi. The kit also contains the superheater assembly, the dome cover, and the fusible plug for the firebox. The superheaters consist of concentric inner and outer tubes, with the outer stainless steel tubes having caps welded onto their rear ends. There's nothing to assemble at this stage, apart from screwing the fusible plug into the top of the inner firebox.

11/11/06

I've ordered a set of boiler blanking plugs from Steamfittings (www.steamfittings.co.uk). They are making up a set of 15 for the Modelworks Britannia (including one for the fusible plug). I plan to have the boiler pressure tested at my local club, so that I can see it withstand 200 psi with my own eyes.

14/11/06

The boiler blanking plugs arrived this morning and I fitted them. I'm not quite sure what all the holes in the boiler are for - there is a hole at the lower front corner on each side of the firebox, but only one blowdown valve included in kit 16; and there are two inlets for clack valves on the rear face of the firebox and two on the top of the boiler towards the front, but as far as I can see there are just two feeds from the injectors plus one from the tender pump and axle pump which are piped in series. Doubtless all will become clear when the next kit arrives. In the meantime, I'll continue painting the tender body.

7/12/06

I'd noticed that the superheater pipe connectors don't line up correctly with the threaded pipes linking them to the cylinder inlet pipes, and so I returned them to Debbie today when I visited the factory to collect my redrilled smokebox. Ted has the same problem with his, so it probably affects all the first batch of boilers. The curved pipes need to be re-aligned, and the threaded pipes need shortening.

7/12/06

I'd noticed that the superheater pipe connectors don't line up correctly with the threaded pipes linking them to the cylinder inlet pipes, and so I returned them to Debbie today when I visited the factory to collect my redrilled smokebox. Ted has the same problem with his, so it probably affects all the first batch of boilers. The curved pipes need to be re-aligned, and the threaded pipes need shortening.

12/12/06

Ted went to Modelworks today to get his superheater pipes adjusted, and brought mine back at the same time. They now fit nicely.

23/4/07

I've spoken to David who does the boiler testing at the St Albans and District MES, one of the local clubs that I belong to, and he has agreed to inspect and test my boiler. However, one minor problem that I've noticed recently is that the bushes for the water gauge fittings do not line up properly, which would make the glasses difficult to fit. I've arranged with Debbie to take the boiler back to Daventry tomorrow so that they can realign the bushes - apparently it's just a matter of screwing in a threaded bar and levering them into alignment, the copper being relatively malleable. Debbie also confirmed that the final kit is still awaiting the delivery of the replacement throatplate castings, which are currently in transit by sea.

24/4/07

I took the boiler up to Daventry this morning, and Debbie and Ian realigned the water gauge bushes - they used a thick steel rod about a foot long with threaded ends, and the bushes were gently levered into the correct alignment. The copper is quite soft and not too much force was needed. They also realigned the large bush for the steam delivery pipe on the front tubeplate, which was slightly out of line and might have caused problems in fitting the regulator, although this wasn't obvious until the rod was screwed in. I also took the opportunity to run a tap through some of the bushes which were a tight fit for the blanking plugs - I think they were probably clogged with PTFE tape from the pressure test. I met Steve Baldock and he said that the ship with the throatplate castings was due into port today after a 45 day voyage - I had wondered why they couldn't be air freighted, but apparently the consignment weighs 3 tons and includes many other castings such as the Foden cylinder blocks. The castings will still need machining and the boiler and firebox cladding will then be made to fit, so I guess that the final kit must still be 2 or 3 weeks away. Debbie promised to keep me updated on progress. I've arranged for David to come and inspect and perhaps pressure test my boiler on Thursday morning, so I'll give another update after that.

26/4/07

David came round this morning and inspected the boiler and gave it a hydraulic pressure test. We fitted all the blanking plugs with PTFE tape, apart from the manifold bush on top of the firebox which was used to fit the pipe from the test equipment. We filled the boiler to the brim with water through the dome and then fitted the dome cover with its paper gasket - no sealant was needed on the gasket for this test. We pumped some water through while rocking the boiler around to eliminate the last bubbles of air through the small hole in the centre of the dome cover, and then put a screw into this hole. David then raised the pressure to 100psi with a few strokes of the pump, checked for leaks and then gradually raised the pressure to 180psi, twice working pressure. The boiler held this pressure with no problems, so David was satisfied with this initial test and indeed with the general construction of the boiler. I know there's a school of thought that the boiler should only be tested once to 2 x wp, and thereafter to 1.5 x wp, and Modelworks have already tested it to 200psi, but I must say that I felt more comfortable to have seen it withstand 2 x wp with my own eyes! The next step is to do another pressure test at 1.5 x working pressure with the boiler fitted to the frames and all the fittings in place, and with a witness present from the club, and then to do a steaming test to ensure that the safety valves work and that there are at least two independent means of getting water into the boiler. David also suggested that we pressure test the axle pump beforehand to avoid having to dismantle everything if it leaks, so I'll remove it from the frames and take it round to his house at some stage to do this.

26/5/07

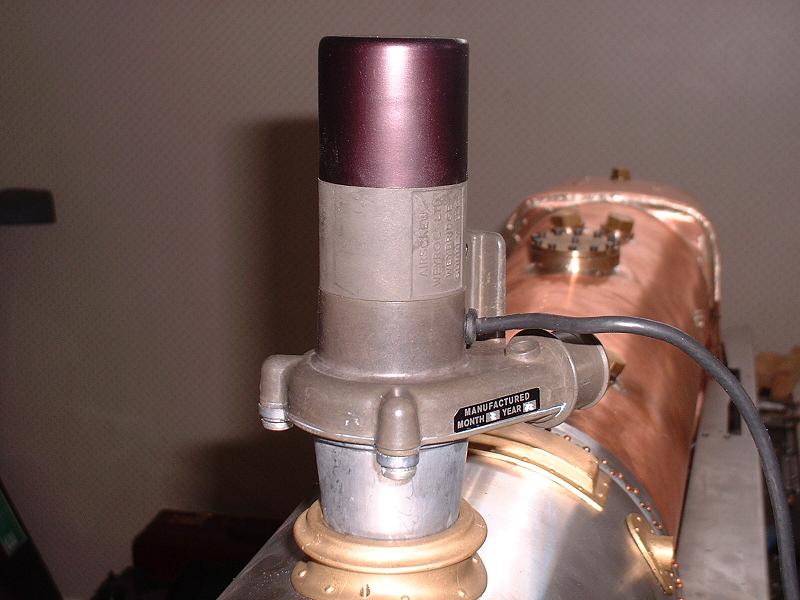

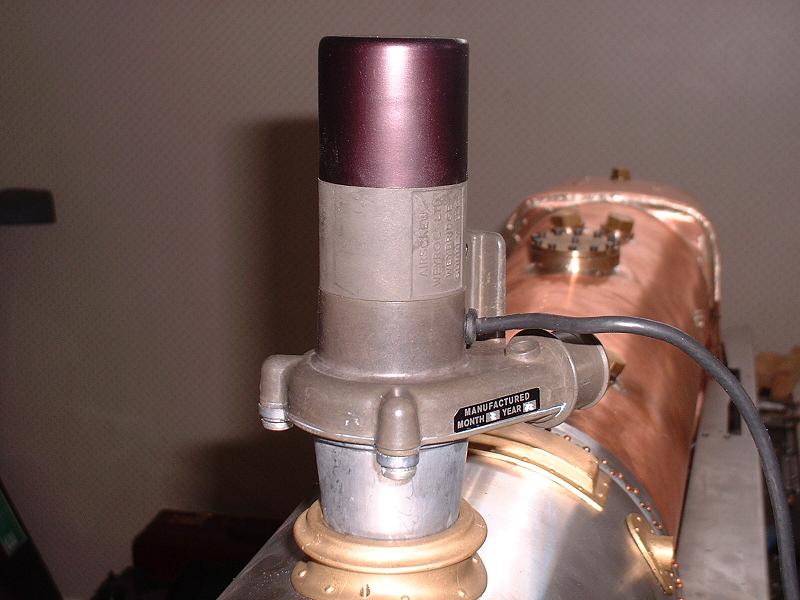

I've bought a steam-raising blower from Steamfittings (www.steamfittings.co.uk). This is military surplus made in 1978, but new and unused and looks very solidly built. It comes with a tapered aluminium adaptor (the larger of the two on offer) that fits the Britannia chimney very nicely as shown in the picture, and seems remarkably good value at £16 plus £2.95 p&p. It's rated at up to 24 volts but runs very vigorously on a spare 18v hedgetrimmer battery that I happen to have.

26/5/07

I've bought a steam-raising blower from Steamfittings (www.steamfittings.co.uk). This is military surplus made in 1978, but new and unused and looks very solidly built. It comes with a tapered aluminium adaptor (the larger of the two on offer) that fits the Britannia chimney very nicely as shown in the picture, and seems remarkably good value at £16 plus £2.95 p&p. It's rated at up to 24 volts but runs very vigorously on a spare 18v hedgetrimmer battery that I happen to have.

18/5/08

Ted and I took our boilers along to the North London club track near St Albans this morning to have the formal hydraulic boiler tests done. Although I'd already had an informal test by the St Albans club tester over a year ago, I thought it better to have the formal test done by the NLSME since that's where I plan to run the loco - I'm a member of both clubs. Both boilers were tested to 180psi and passed without any problems - the tester was very happy with the standard of construction. I removed all the cladding from my boiler because I found that some of my blanking plugs would not screw right down through the holes in the cladding; Ted had his tested with the cladding on and all the fittings in place. These hydraulic test certicates are valid for 4 years, and we will now both aim to do a steam test as soon as possible once we get our regulator adaptors from Modelworks.

9/11/06

I visited the factory today to collect my boiler. It's a very impressive piece of craftsmanship - 26 kilos of copper, beautifully silver soldered. It comes with a test certificate and CE declaration of conformity, having been pressure tested to 200 psi with a working pressure of 90 psi. The kit also contains the superheater assembly, the dome cover, and the fusible plug for the firebox. The superheaters consist of concentric inner and outer tubes, with the outer stainless steel tubes having caps welded onto their rear ends. There's nothing to assemble at this stage, apart from screwing the fusible plug into the top of the inner firebox.

9/11/06

I visited the factory today to collect my boiler. It's a very impressive piece of craftsmanship - 26 kilos of copper, beautifully silver soldered. It comes with a test certificate and CE declaration of conformity, having been pressure tested to 200 psi with a working pressure of 90 psi. The kit also contains the superheater assembly, the dome cover, and the fusible plug for the firebox. The superheaters consist of concentric inner and outer tubes, with the outer stainless steel tubes having caps welded onto their rear ends. There's nothing to assemble at this stage, apart from screwing the fusible plug into the top of the inner firebox.